C2410F SMD FUSE

Brand : Songshan

Product origin : Shanghai

Delivery time : 7-15 days

Supply capacity : 15000000

SMD C2410F series are suitable for overcurrent protection of primary and secondary circuit boards of various electronic equipment. It is widely used in green lighting, consumer electronics, power supply, network communication, UAV, medical instruments and industrial controllers.

1. Electrical Characteristics

Ampere Rating | % of Current Rating | Opening Time |

0.5-30A | 100% | Min.4hours |

200% | Max120sec |

2. Electrical Specifications

Part Number |

Current Rating(A) |

Voltage Rating(V) |

Interrupting Capacity | Typical Cold DCR(mΩ) |

Nominal I²T* (A²s) |

Marking |

2410-F-0.50A | 0.50 |

125VDC/250VAC |

100A@125VDC 100A@250VAC 300A@48VDC | 0.225 | 0.10 | A |

2410-F-0.63A | 0.63 | 0.171 | 0.12 | B | ||

2410-F-0.75A | 0.75 | 0.117 | 0.23 | C | ||

2410-F-1.0A | 1.00 | 0.090 | 0.42 | D | ||

2410-F-1.25A | 1.25 | 0.070 | 0.62 | E | ||

2410-F-1.50A | 1.50 | 0.063 | 0.73 | F | ||

2410-F-1.60A | 1.60 | 0.055 | 1.10 | U | ||

2410-F-2.00A | 2.00 | 0.036 | 2.50 | H | ||

2410-F-2.50A | 2.50 | 0.030 | 3.30 | I | ||

2410-F-3.00A | 3.00 |

125VDC/125VAC |

100A@125VDC 100A@125VAC 300A@48VDC | 0.024 | 0.9 | J |

2410-F-3.15A | 3.15 | 0.023 | 1.0 | K | ||

2410-F-3.50A | 3.50 | 0.020 | 2.4 | V | ||

2410-F-4.00A | 4.00 | 0.017 | 3.2 | L | ||

2410-F-5.00A | 5.00 | 0.014 | 5.0 | M | ||

2410-F-6.30A | 6.30 |

125VDC |

50A@125VDC 300A@48VDC | 0.0118 | 6.1 | N |

2410-F-7.00A | 7.00 | 0.0099 | 9.8 | O | ||

2410-F-8.00A | 8.00 | 0.0082 | 14.2 | P | ||

2410-F-10.0A | 10.0 | 0.0071 | 22.5 | Q | ||

2410-F-12.0A | 12.0 | 0.0049 | 43.2 | R | ||

2410-F-15.0A | 15.0 | 0.0038 | 67.5 | S | ||

2410-F-20.0A | 20.0 |

72VDC |

60A@72VDC 300A@48VDC | 0.0031 | 116 | T |

2410-F-25.0A | 25.0 | 0.0024 | 153 | X | ||

2410-F-30.0A | 30.0 | 0.0019 | 252 | Y |

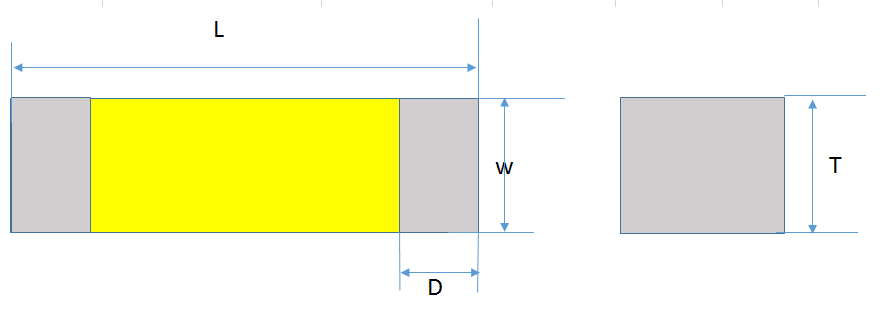

3. Dimensions

Type | L | W | T | D |

(mm) | (mm) | (mm) | (mm) | |

C2410 | 6.1±0.20 | 2.50±0.2 | 2.1±0.2 | 1.40±0.35 |

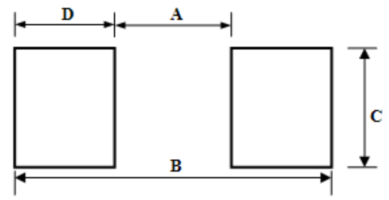

4. Recommended Land Patterns

Dimensions | Spec |

A(mm) | 3.0 |

B(mm) | 8.0 |

C(mm) | 3.0 |

D(mm) | 2.5 |

5. Materials

Components | Material |

Body | Epoxy flame retardant materials |

Fuse-element | Copper alloy |

Terminations | Tin Plated Copper |

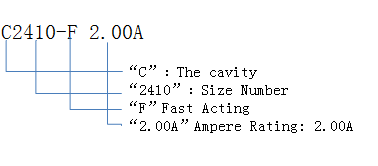

6. Part Number Information

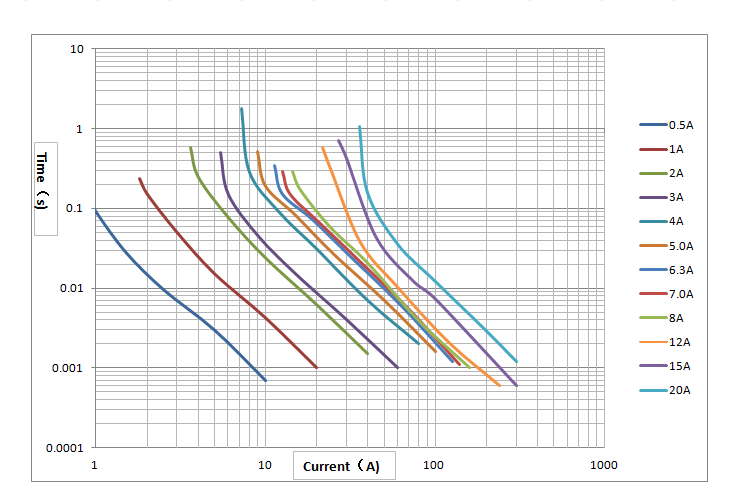

7. Time Current Curve

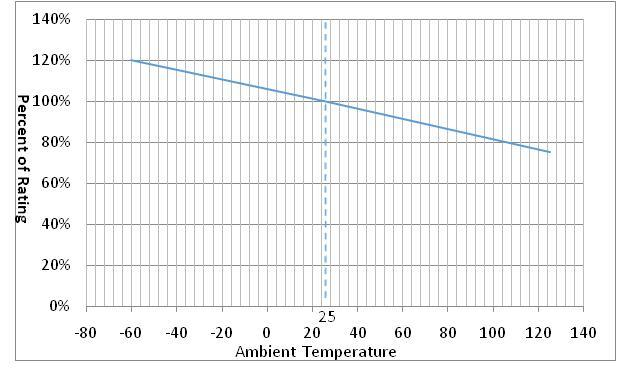

8. Temperature Re-rating Curve

When choosing the fuse's specification,if the operating Environmental temperature beyond the scope from 20~30℃,engineer should consider the environmental temperature's Affection to fuses.Please refer Temperature Re-rating Curve.

9. Product Characteristics

Item | Test condition | Performance | Standard |

Time/Current | 100% of current rating | 4hr Min | UL248-14 |

200% of current rating . | 60sec Max | Factory SPEC | |

1000%of current rating | 10msec Max | Factory SPEC | |

Interrupting Ability | 250VAC100A 125VDC100A 125VAC50A 65VDC50A 48VDC300A | without permanent arcing,ignition and bursting of fuse link | UL248-14 |

Solder ability | 240℃±5℃,3sec±0.5sec, | 90% coverage Min. | MIL-STD-202 |

Resistance to Soldering Heat | 260℃±5℃,10sec±0.5sec, | |△R|: <10% | MIL-STD-202 |

Moisture resistance | 10 cycle | |△R|: <10%., no mechanical damage | MIL-STD-202 |

Salt Spray | 5%±1% salt solution ,48hours | |△R|: <10% | MIL-STD-202 |

Mechanical Shock | Test Condition I: Deenergized. 100G’s peak | |△R|: <10%., no mechanical damage | MIL-STD-202 |

Mechanical Vibration | Amplitude 10Hz~55Hz in 1 min. 2 hours,each XYZ, total 6 hours | |△R|: <10%., no mechanical damage | MIL-STD-202 |

Thermal Shock | -65°C to +125°C, 100 cycles, | |△R|: <10%., no mechanical damage | MIL-STD-202 |

10. Storage

Packaged Fuse should be storage at ambient temperature for -10~+40 ℃ relative humidity below 80%,the warehouse of Ambient air in non-acidic, non-alkaline or other no corrosive gases,Before use, need to confirm the aluminum foil bag sealing intact.

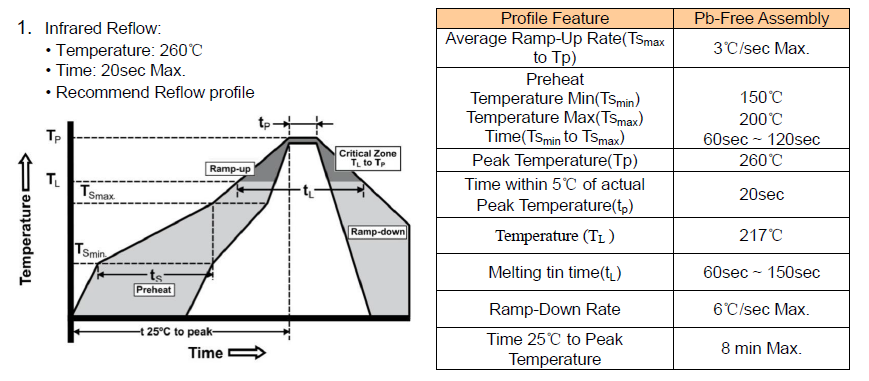

11. Recommended Solder Curve

12.Packaging

Tape(mm) | Reel(inch) | Quantity |

12.5 | 7 | 2000 |

13. Others

This product is fully in line with the EU ROHS requirements!